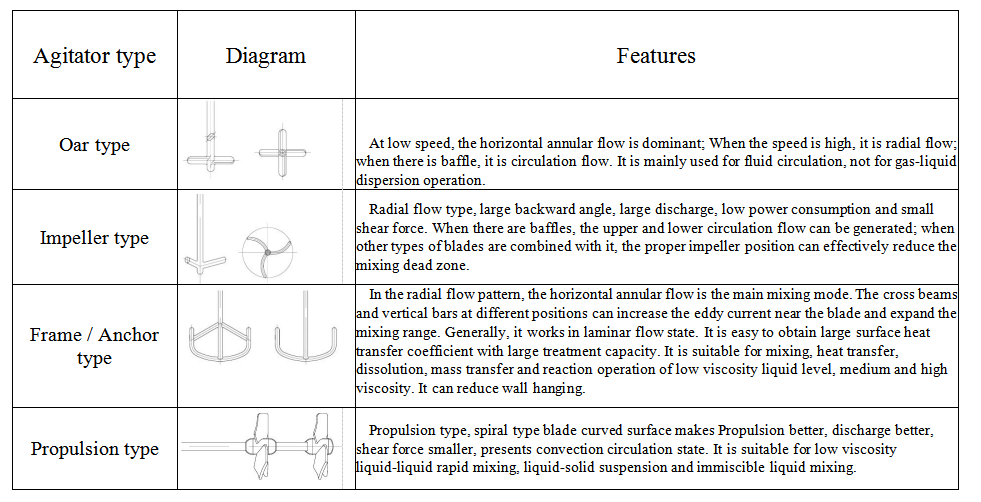

Types and type selection reference of glass lined agitator

When selecting agitators, the following should be considered:

1. Properties of media: viscosity, density, corrosivity;

With the increase of medium viscosity, the order of various agitators to be choosen is: paddle type, propulsion type, turbine type, frame type and anchor type, screw (belt) type.

2. The characteristics of the reaction process;

3. Mixing effect and mixing power requirements.

Agitator type. | Flow state | Purpose of mixing | Volume of mixing vessel m3 | revs range r/min | Maximum viscosity pa.s | ||||||||||

Convective circulation | Turbulent diffusion | Shear flow | Low viscosity mixing | Mixing heat transfer reaction of high viscosity liquid | dispersed | dissolution | Solid suspension | Gas absorption | Crystallize | Heat transfer | Liquid phase reaction | ||||

Turbine type | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | 1—100 | 10—300 | 50 |

Oar type | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | 1—200 | 0.5〜300 | 2 | ||

propulsive impeller | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | 1 〜1000 | 10 〜500 | 50 | |||

Vane opening turbine type | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | 1 〜1000 | 10~300 | 50 | ||||

Brumagin type | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | 1 〜100 | 10 〜300 | 50 | ||||

Anchor type | ♦ | ♦ | ♦ | 1 〜100 | 1 〜100 | 100 | |||||||||

Screw type | ♦ | ♦ | ♦ | 1〜50 | 0.5 〜50 | 100 | |||||||||

Ribbon type | ♦ | ♦ | ♦ | 1〜50 | 0.5 〜50 | 100 | |||||||||

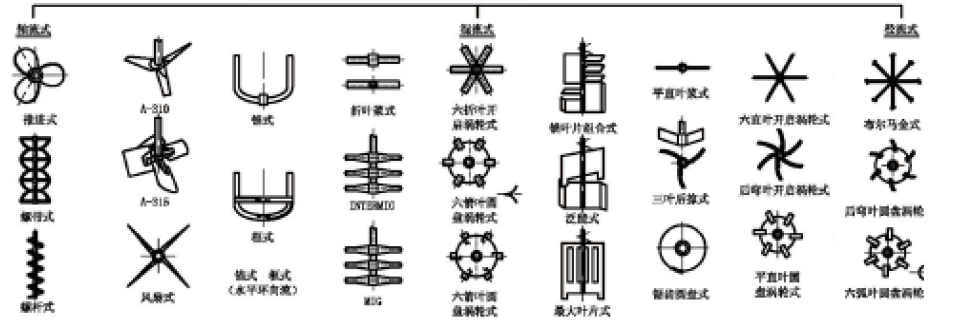

Classification Atlas of agitator flow pattern

Glass Lined Wing Propulsion Agitator

The glass lined wing axial-flow Agitator developed by Beijing Huateng DaTang Equipment Co., Ltd. has passed the provincial appraisal and obtained the national patent. The product is innovated in structure, with good mixing effect, high efficiency and energy saving, reaching the international advanced level.

There are four characteristics of glass lined wing Propulsion Agitator

1. It has the advantages of Propulsion, strong pumping capacity and large circulation capacity. It can form ideal Propulsion and is conducive to full mixing. It is suitable for liquid-liquid rapid mixing, liquid-solid suspension and immiscible liquid mixing。

2、The results were compared under different stirring conditions showed that the shear force was mild and the droplet distribution was uniform

Paddle type | Particle size distribution (%) | ||||

d/T=0.6 | <0.63 | 0.63~0.90 | 0.90~2.00 | 2.00^3.00 | >3.00 |

Two layers hydrofoil Paddle | 2.9 | 9.8 | 79.8 | 7.4 | 0.0 |

Three layers hydrofoil Paddle | 2.3 | 8.4 | 85.1 | 4.1 | 0.1 |

Four layer flat Paddle | 1.0 | 4.9 | 70.6 | 22.7 | 0.0 |

3、The energy saving effect is obvious, and the process yield of some products is obviously improved.

Comparison of agitator power consume | Mixing time and related power | ||||||

Specifications | Wing Propulsion | Traditional agitator | Paddle type | anchor type | Brumagin type | Hydrofoil type | |

1000L | 1.1kw | 4.0kw | Relative value of mixing time | 100 | 70~80 | 50~53 | |

2000L | 2.2kw | 4.0kw | Power relative value | 100 | 65 | 52 | |

3000L | 3.0kw | 5.5kw | |||||

5000L | 3.0kw | 7.5kw | |||||

8000L | 7.5kw | 11kw | |||||

10000L | 7.5kw | 11kw | |||||

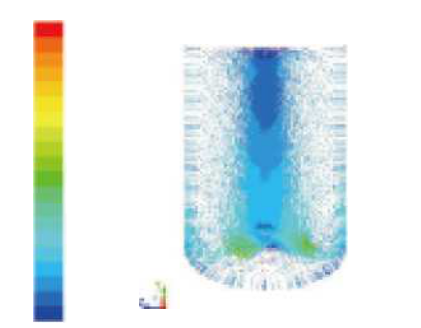

4、Heat transfer enhancement in autoclave.

Agitator type 、 Specification of reactor | Nominal diameter of Agitator shaft | Impeller type /Oar type / Combined type / Propulsion type | Anchor type / frame type | |||

DN | B | B1 | H | B | H | |

FK50-50 | 40 | 250 | 250 | 830 | 450 | 880 |

FK60-100 | 50 | 360 | 360 | 960 | 520 | 1000 |

FK70-200 | 50 | 420 | 420 | 1200 | 620 | 1240 |

FK80-300 | 65 | 480 | 480 | 1350 | 720 | 1390 |

FK90-500 | 65 | 540 | 540 | 1540 | 810 | 1620 |

FK120-1000 | 80 | 700 | 700 | 1900 | 1080 | 1900 |

FK130-1500 | 80 | 700 | 700 | 2140 | 1180 | 2140 |

FK130-2000 | 80 | 700 | 700 | 2480 | 1180 | 24B0 |

FK160-3000 | 95 | 800 | 700 | 2630 | 1440 | 2630 |

FK175-5000 | 95 | 850 | 750 | 3190 | 1580 | 3190 |

FK175-6300 | 95 | 850 | 750 | 3660 | 1580 | 3660 |

FK200-8000 | 130 | 1100 | 880 | 4040 | 1720 | 4040 |

FK200-10000 | 130 | 1100 | 880 | 4440 | 1720 | 4520 |

FF160-3000 | 95 | 800 | 700 | 2630 | / | / |

FF175-5000 | 95 | 850 | 700 | 3190 | / | / |

FF175-6300 | 95 | 850 | 700 | 3660 | / | / |

FF200-8000 | 130 | 1100 | 880 | 4040 | / | / |

FF200-10000 | 130 | 1100 | 880 | 4440 | / | / |

FF220-10000 | 130 | 1200 | 880 | 4200 | / | / |

FF220-12500 | 130 | 1200 | 880 | 4730 | / | / |

FF240-16000 | 130 | 120 | 880 | 4890 | / | / |

FF260-20000 | 130 | 1300 | 1080 | 5325 | / | / |

FF280-25000 | 140 | 1300 | 1080 | 5691 | / | / |

FF320-30000 | 140 | 1500 | 1300 | 5530 | / | / |

FF340-40000 | 140 | 1500 | 1300 | 6268 | / | / |

FF380-50000 | 160 | 1500 | 1300 | 5988 | / | / |

Note: The length of agitator is :Reactor below 6300 L equipped with type 79 standard Frame, Reactor over 8000L Calculate as type 4ZTJ frame

Glass lined thermowell

Thermowell type

Specification of reaction tank | Nominal diameter of thermometer | Impeller /Oar Combined /Propulsion | Anchor/ Frame | ||

DN | Stright Tube H (mm) | Flat Tube H (mm) | Stright Tube H (mm) | Flat Tube H (mm) | |

FK50-50 | 32 | 430 | 550(Anchor type) | ||

FK60-100 | 32 | 530 | 650( Anchor type ) | ||

FK70-200 | 32 | 680 | 900( Anchor type ) | ||

FK80-300 | 32 | 810 | 1000( Anchor type ) | ||

FK90-500 | 32 | 1000 | 770 | ||

FK120-1000 | 65 | 1305 | 1000 | ||

FK130-1500 | 65 | 1735 | 1150 | ||

FK130-2000 | 65 | 1510 | 1510 | ||

FK160-3000 | 65 | 1510 | 1510 | ||

FK175-5000 | 80 | 1775 | 1775 | ||

FK175-6300 | 80 | 2165 | 2165 | ||

FK200-8000 | 140 | 3100 | 3100 | 2210 | 2210 |

FK200-10000 | 140 | 3400 | 3400 | 2500 | 2500 |

FF160-3000 | 65 | 1510 | |||

FF175-5000 | 80 | 1775 | |||

FF175-6300 | 80 | 2165 | |||

FF200-8000 | 140 | 2700 | 2700 | ||

FF200-10000 | 140 | 3400 | 3400 | ||

FF220-10000 | 140 | 2900 | 2900 | ||

FF220-12500 | 140 | 2900 | 2900 | ||

FF240-16000 | 140 | 2900 | 2900 | ||

FF260-20000 | 140 | 3100 | 3100 | ||

FF280-25000 | 140 | 3400 | 3400 | ||

FF320-30000 | 140 | 3400 | 3400 | ||

FF340-40000 | 160 | 3800 | 3800 | ||

FF380-50000 | 160 | 3800 | 3800 | ||

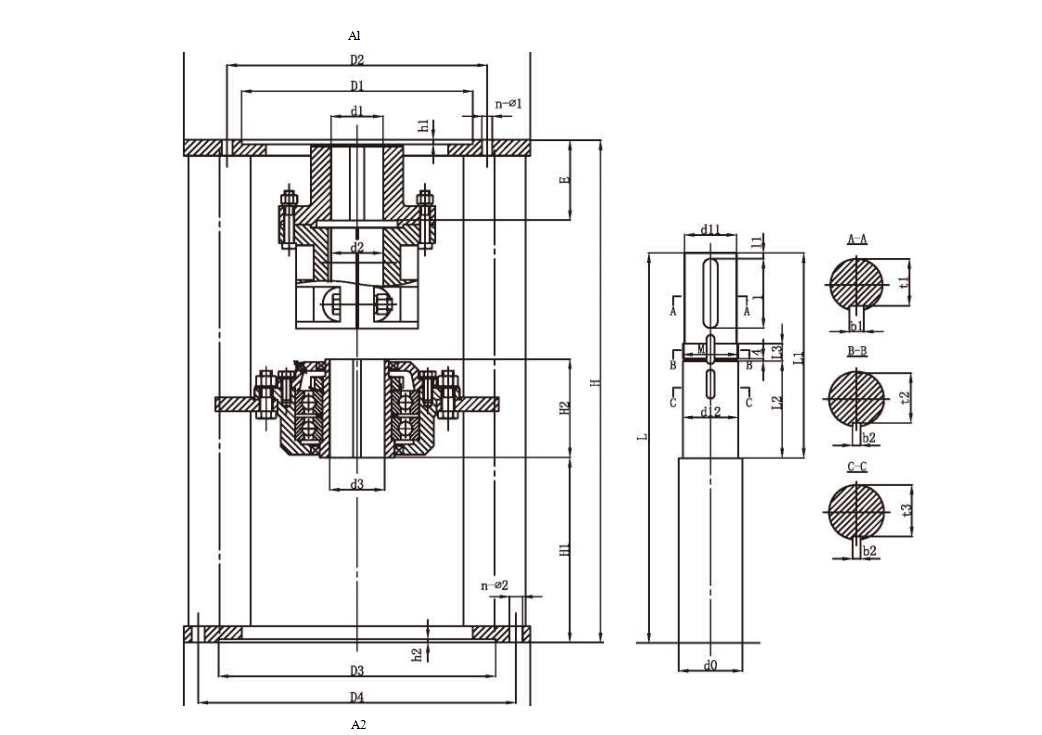

Parameters and dimensions type 4ZTJ Frame

Type | H | H1 | H2 | d2 (H8) | d3 (H9) | Reducer connector | Reactor interface | Weight (Kg) | ||||||||||

A1 | D1(H8) | D2 | H1 | d1 | E | A2 | D3(H9) | D4 | h2 | n-Φ2 | ||||||||

4Z80 | 620 | 247 | 125 | Φ55 | Φ65 | 350X350 | Configuration According to Reducer | Φ450 | Φ325 | Φ400 | 6 | 4-Φ27 | 100 | |||||

4Z95 | 700 | 250 | 145 | Φ65 | Φ76 | 400x400 | Φ500 | Φ350 | Φ450 | 6 | 4-Φ27 | 139 | ||||||

4Z110 | 870 | 320 | 170 | Φ90 | Φ95 | 600x600 | 600x600 | Φ480 | Φ550 | 8 | 12-Φ27 | 310 | ||||||

4Z130 | 930 | 320 | 180 | Φ100 | Φ110 | 600x600 | 600x600 | Φ480 | Φ550 | 8 | 12-Φ27 | 360 | ||||||

4Z140 | 1050 | 390 | 180 | Φ110 | Φ125 | 650x650 | 700x700 | Φ560 | Φ650 | 10 | 16-Φ27 | 500 | ||||||

机型 | Size of agitator shaft head | Size of agitator shaft head | |||||||||||||

d0 | dl(js8) | d12(19) | M | L | L1 | L2 | L3 | 1 | 11 | b1 | b2 | t1 | t2 | t3 | |

4Z80 | Φ80 | Φ55 | Φ65 | M64x2 | 490 | 245 | 122 | 22 | 22 | 5 | 16 | 8 | 49 | 60 | 61 |

4Z95 | Φ 95 | Φ65 | Φ76 | M76X2 | 540 | 290 | 142 | 22 | 22 | 8 | 18 | 10 | 58 | 70 | 71 |

4Z110 | Φ110 | Φ90 | Φ95 | M95X2 | 675 | 355 | 168 | 30 | 30 | 10 | 25 | 12 | 81 | 89 | 90 |

4Z130 | Φ125 (Φ130) | Φ95 | Φ110 | M110X2 | 688 | 368 | 178 | 30 | 30 | 10 | 28 | 14 | 86 | 104 | 104.5 |

4Z140 | Φ140 | Φ110 | Φ120 | M120x2 | 806 | 416 | 182 | 30 | 30 | 10 | 28 | 14 | 100 | 114 | 114.5 |

Products

Products