Glass lined / stainless steel double cone rotary vacuum dryer

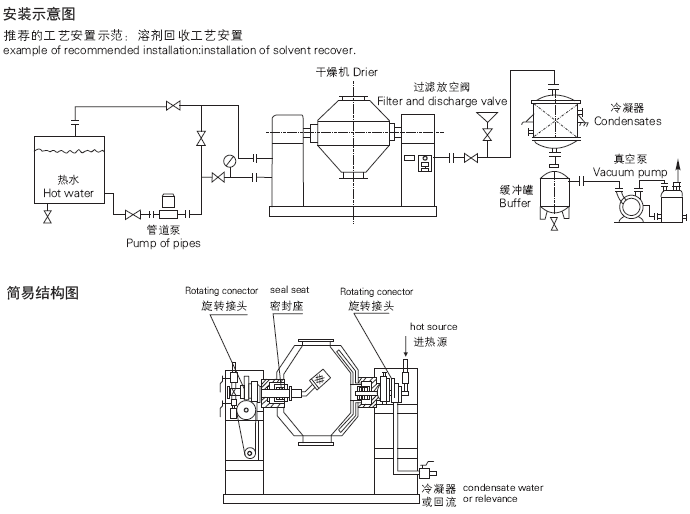

GSZ double cone rotary vacuum dryer produced by our company can be divided into GSZ Ⅰ glass lined type and GSZ Ⅱ stainless steel type according to the material of inner tank. According to the different properties of materials required by customers, customers can choose according to their needs. In the production and sales of more than ten years, our company has made a variety of breakthroughs in the glass enamel double cone rotary dryer through continuous innovation and improvement according to the actual needs of customers, overcoming a variety of difficulties in enamel technology. In the drying performance and ensure the purity of materials in the international advanced level.

The picture shows the cone of glass lined inside tank

The unique form of vacuum net cover eliminates the secondary pollution of materials and is easy to disassemble.

The gap between the stainless steel insulation layer and the cylinder is solved, which meets the requirements of the new GMP. When the stainless steel type double cone rotary vacuum dryer is used to dry sticky materials, our factory will specially design a "plate" mechanism or set up a bearing ball in the tank. Solve the problem of material agglomeration.

Product overview

SZG double cone vacuum dryer is a new generation drying device developed by our factory in combination with domestic similar product technology. Double cone vacuum adopts belt chain two elastic connection modes, so the equipment runs smoothly. The specially designed process fully embodies the good concentricity of the two shafts. The heat medium and vacuum system adopt reliable mechanical seal or rotary joint of American technology. Based on these, we developed SZG-a, which can not only Stepless-speed regulation, but also constant temperature control.

As a professional drying equipment manufacturer, our products are available from high temperature heat transfer oil as heat medium, medium temperature steam and low temperature hot water. When drying sticky materials, our factory will specially design a "plate " mechanism or set bearing balls in the tank .

Details

Working Principle

◎Let heat source(for example,low pressure steam or thermal oil)pass through the sealed Jacket The heat will be transmitted to raw material to be dried through inner shell;

◎Under driving of power, the tank is rotated slowly and the raw material inside it is mixed continuously. The purpose of reinforced drying can be realized;

◎The raw material is under vacuum The drop of steam pressure makes the moisture(solvent)at the surface of raw material become saturation and will evaporate The solvent will be discharged through vacuum pump and recovered in time The inner moisture(solvent)of raw material will infiltrate,evaporate and discharge continuously The three processes are carried out unceasingly and the purpose of drying can be realized within a short time.

Material to be dried

It is suitable for the raw materials that need to concentrate, mixed and dried at low temperature(for example, biochemistry)products in chemical, pharmaceutical and foodstuff industries. Particularly it is suitable for the raw materials that are easy to be oxidized, volatilized and have night heat sensitivity and is toxic and not permitted to destroy its crystal in drying process.

Characteristics

◎When oil is used to heat,use automatic constant temperature control .It can be used for drying biology products and mine Its temperature of operation can be adjusted form 20—160oC.

◎Compared to ordinal dryer, its heat efficiency will be 2 times higher.

◎The heat is indirect So the raw material can not be polluted.

◎It is in conformity with the requirement of GMR It is easy in washing and maintenance.

Technical Parameter

model | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

Tank volume (L) | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 |

Loading volume of raw material (L) | ≤50 | ≤175 | ≤250 | ≤375 | ≤500 | ≤750 | ≤1000 | ≤1750 | ≤2250 | ≤2500 |

Heating area (m2) | 1.16 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 11.2 | 13.1 | 14.1 |

Revolution ( rpm) | 4 - 6 | |||||||||

power of motor (kw) | 0.75 | 1.1 | 1.5 | 2 | 3 | 3 | 4 | 5.5 | 7.5 | 11 |

Occupied area, L×W (mm) | 2160×800 | 2260×800 | 2350×800 | 2560×1000 | 2860×1300 | 3060×1300 | 3260×1400 | 3760×1800 | 3960×2000 | 4400×2500 |

rotating height (mm) | 1750 | 2100 | 2250 | 2490 | 2800 | 2940 | 2990 | 3490 | 4100 | 4200 |

design pressure inside the tank (MPa) | -0.1-0.15 | |||||||||

design pressure of jacket (MPa) | ≤0.3 | |||||||||

working temperature (°C) | In the tank≤85 jacket≤140 | |||||||||

Using condensator, | 2X-15A | 2X-15A | 2X-30A | 2X-30A | 2X-70A | JZJX300-8 | JZJX300-4 | JZJX600-8 | JZJX600-4 | JZJX300-4 |

model and power of vacuum pump | 2KW | 2KW | 3KW | 3KW | 505KW | 7KW | 9.5KW | 11KW | 20.5KW | 22KW |

Shutoff condensator, | SK-0.4 | SK-0.8 | SK-0.8 | SK-2.7B | SK-2.7B | SK-3 | SK-6 | SK-6 | SK-9 | SK-10 |

model and power of vacuum pump | 1.5KW | 2.2KW | 2.2KW | 4KW | 4KW | 5.5KW | 11KW | 11KW | 15KW | 18.5KW |

Weight (kg) | 800 | 1100 | 1200 | 1500 | 2800 | 3300 | 3600 | 6400 | 7500 | 8600 |

Products

Products